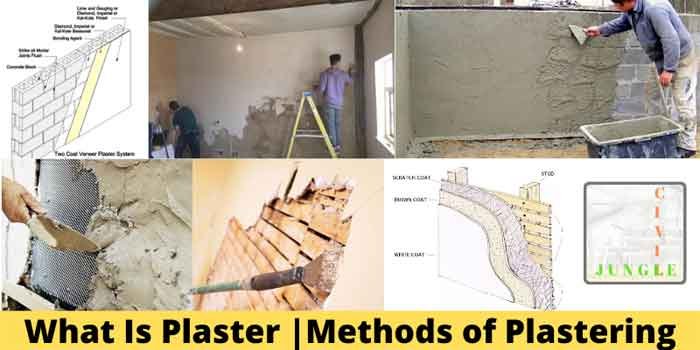

The process of applying a layer or covering to obtain smooth and consistent texture on ceilings, walls, and other surfaces is referred to as plastering. Cement plastering is an essential component of the preservation process. The many sorts of plasters and their significance are elaborated on in the article below.

Plaster is used as a coating material for walls and ceilings during the construction processes. It is a mixture of dry powder, which is mixed with water when it is about to be used for construction.

The material is used in every construction process, in fact, constructing a building without using plaster is practically impossible. Plasters form a hard coat that hides the bricks.

There are various types of plasters available in the market that are used in various types of constructions; these can be also designed with the use of different types of stones and gravels.

What is Plastering Work? Why Should You Do It?

Wall plastering is a very old trade that has been around for centuries, and it is still an important part of construction today.

Maybe you’re renovating an old home and want to add some character. Whatever your reason is, plastering the walls and roof can add beauty and value to your property. It is popularly used as wall art as well and has different trends nowadays like gypsum plastering, portland plastering, lime plastering, sandstone plastering, GFRG plastering, metal lath plastering, etc.

Check cement sand ratio for plastering here before you get the work started to get an idea on the ratio of sand and cement to be used for plastering work which is best.

It is also good for decorating the walls as well, especially if you can incorporate patterns and textures into your plastering.

When Plastering, Keep the Following in Mind

First, plastering is not a do-it-yourself job or work. It’s best to hire a professional who has the experience and knows what they’re doing.

Second, plastering can be messy and time-consuming. It’s important to be prepared for the mess and have patience while the job is being done.

Once you’ve decided to plaster your walls or ceilings, the next step is to choose the right materials.

- Lime plaster is made from limestone and other minerals, while gypsum plaster is made from calcium sulfate.

- The aggregates must be washed thoroughly to ensure that no more than 5% clay is present in the sand. To get the correct consistency, thoroughly combine the aggregates and binder.

- The plaster mix must be followed precisely. To avoid crazing on plastered surfaces, keep an eye on the amount of water in the mortar.

- Salt deposits will form if the plaster is not allowed to dry slowly, as this can cause crazing, which destroys the plaster job.

- The water and aggregate should be free of any minerals or contaminants. When soluble salts are included in the mixture, salt crystallization will occur and the plastered surface will begin to fall apart or powder.

- It’s recommended that you knock off the projections extending beyond 13 mm from the masonry’s overall surface.

- All loose dust and mortar should be removed from these joints.

- A single coat of plaster should not be thicker than 15 millimeters.

- Before plastering, the wall surface should be moistened.

- The plaster must be applied along the whole length of a wall or as high as doors or windows are positioned.

- To get an idea of cement sand ratio for brickwork refer to this.

Plastering Work Techniques

Here’s a list of some of the techniques that may be used in lime plastering or cement plastering:

- Dry-pack: This is the process of packing dry plaster mix into a mold or area to be plastered.

- Wet-pack: This is the process of mixing plaster with water to create a slurry, which is then packed into a mold or area to be plastered.

- Floating: This technique is used to create an even, level surface.

- Sponging: This technique is also used to create a textured finish.

- Combing: This technique is used to create decorative patterns in plaster.

Many other techniques can be used in plastering, but these are some of the most common. You should also know a bit about coarse aggregate before you start the plastering work as coarse aggregate and fine aggregate are used for different types of plastering work.

Have a look at the difference between coarse aggregate and fine aggregate here.

These are the types of plastering work that are used widely and its calculation:

Different Types of Plastering

Various types of plastering can be used to create different looks and finishes on walls and ceilings.

1. Sandstone Plastering

Sandstone plastering is a type of plastering that uses sandstone as the main material. This type of plastering is usually applied to walls and ceilings to create a smooth, stone-like finish.

2. Lime Plastering For Internal Walls

Lime plastering is ideal for use on internal walls as it allows the wall to breathe, prevents dampness and condensation, and has a very low carbon footprint. It is also extremely strong and durable.

If you are looking for a natural alternative to traditional plastering methods, then lime plastering could be the perfect solution for you.

3. Gypsum Plastering

Gypsum plastering is a type of plastering that uses gypsum as the main binding agent. This type of plastering is usually used on walls and ceilings to create a smooth, white finish.

Have a look at gypsum ceiling design you can choose from when you opt for gypsum plastering to give a unique look to your rooms.

4. Portland Cement Plastering

Cement plastering is an exterior and interior wall finish consisting of Portland cement-based materials. It is usually applied to masonry, concrete, or metal surfaces, but it can also be applied to wood or other materials.

Portland cement plaster can be textured or smooth, and it can be tinted with pigments to produce a wide range of colors. It is durable, easy to maintain, and provides a great finished look.

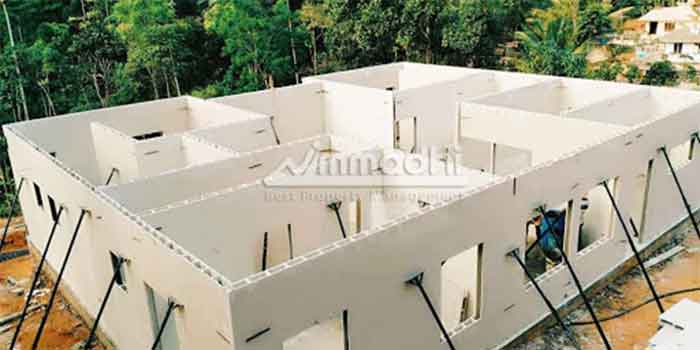

5. Glass Fiber Reinforced Gypsum (GFRG) Plastering

The GFRG panel is made of glass fibers and gypsum, which are mixed and cast into a mold. This type of plastering has many advantages over traditional plastering methods. It is also fire resistant and has a high strength-to-weight ratio.

Another advantage of GFRG plastering is that it can be applied directly to an existing wall without the need for any additional support. This makes it ideal for retrofitting existing buildings.

6. Metal Lath Plastering

There are many benefits to using metal lath plastering instead of standard wood lath plastering. Metal lath is much stronger than wood, so it can support heavier loads without bowing or breaking.

Have a look at the tips on curing brick walls here.

It is also fire resistant and rotproof, so it will last longer in areas that are exposed to high heat or moisture. Metal lath plastering is also easier to install than wood lath plastering, so it can save you time and money on your project.

7. Rough Cast Plaster

It is a mixture of sand and gravel in a specific proportion, and the base of the plaster consists of two coats while the mortar cement ratio of this type of plaster is 1:3. The plaster can be made more plastic by the addition of 10% of hydrated lime by volume of the cement during the preparation of the mortar.

8. Pebbled Dash Plaster

The configuration of the pebbled dash plaster is similar to the roughcast plaster, except that pebbles of the size range of 6 mm to 12.5 mm are dashed against the surface, these pebbles get fixed in their position when the mortar is hydrated and becomes hard.

Consider reading about types of steel bars used in roof slabs and in the walls here.

9. Sand Faced Plaster

The first coat of the sand-faced plaster is applied along with mortar cement in the ratio of 1:4 coupled with coarse sand.

After curing the plaster for one week, the second coat is placed in the ratio of 1:3, while a sponge is used in the second coat during the construction process and it is added to the cement when the cement is wet. The surface should be kept watered at least for 15 days.

10. Plain Face Plaster

The composition of this type of plaster is similar to the sand-faced plaster except fine-grained sand is used instead of coarse sand. The process of sponging is not required in order to expose the coarse sands. This type of plaster is usually applied to the internal walls.

11. De Peter Plaster

It is a type of roughcast finished plaster that renders the coat of 12 mm thickness. When the plaster is wet, pieces of gravel are pressed into them with the hands. Thus, this type of plaster makes it possible to have beautiful designs and patterns on the surface by choosing materials of different colors.

Consider Reading:

Plastering Problems

If the correct proportion of plaster is used, an impervious layer of plaster will function well. Rainwater seeps into cracks in the structure as a result of movement in the building. The moisture that has entered through the cracks increases the dampness and fragility of the construction.

The plaster’s imperviousness further restricts the return of water. As a result, no water can escape because of this accumulation. Water in the walls has no way out since it is trapped for an extended period. To get the greatest benefits, you must execute plastering procedures correctly.

Conclusion

Plastering is a construction process that has been used for centuries to create beautiful, smooth finishes on walls and ceilings.

Is gypsum plastering safe to do on brick walls? If not which type of plastering gives a smooth finish on bricks? I have got gypsum plastering done on my brick walls. The plasterer said that it is safe and will not damage the bricks but I am not sure if he is telling the truth.