The numerous wood types used for veneers seem extremely different and have distinct qualities, but they all have practicality and beauty in common, and they all add warmth to the room you might be working in.

A veneer in woodworking is a paper-thin cutting of the wood material that is put to both sides of a solid core surface, such as home furnishing MDF or substrate property, to bind and stabilize it—which is vital for creating built-in equipment or anything with a mechanism.

The reason for using wood veneer is simple and straightforward. Solid wood contracts and expands with changes in temperature,  and no matter how effective your A/C unit is, your apartment is not climate controlled.

and no matter how effective your A/C unit is, your apartment is not climate controlled.

What is Wood Veneer?

Thin pieces of wood are typically affixed to flattened panels such as doorways, drawers, and walls. Applying wood veneer entails using a less common wood, which may be more difficult to obtain or pricier, and then, veneering it over something cheaper and more widely available.

Many people mistake this for cheap or low-quality wood veneer, which is simply not the case. This is because you frequently encounter veneers that appear cheap, but in most cases, what you are looking at is laminate instead of wood.

Consider reading about engineered wood here as well.

As expected, wood veneers, of course, vary in quality depending on the woodworker’s expertise. Although this process of wood veneering sounds simple, in reality, it is not the case.

Wood veneers can be made to appear seamless by someone with the necessary expertise and experience.

Why use wood veneer?

Veneers are used by architects and woodworkers for both decorative and utilitarian purposes. Aside from the decorative and functional benefits, employing wood veneers is cost-effective.

Rather than using solid and pure wood, which is costly, heavy, and difficult to form on-site, veneers are less expensive and way easier to install. Commercial-grade wood veneer serves significant tasks in anything from hotel ballrooms to private libraries.

Also read about vinyl flooring and its designs here.

There are various advantages of using wood veneers:

- Reliability- Unlike pure wood, wood veneer does not rapidly absorb or emit moisture. As a consequence, veneers are less likely to deform or distort over age. They can resist humidity and temperature fluctuations in the environment.

- Visual appeal- Wood veneers, as a cosmetic component of woodwork, can provide a wide range of aesthetics for your project. Depending on the patterns on the wood, you can utilize several methods of matching, such as grain similarity and sequence matching.

- Environment friendly – If you utilize solid wood, you will almost certainly waste a substantial number of wood chips in the form of dust and unusable little pieces. On the other hand, wood veneers do not have the same issue and are hence more sustainable.

- Genuinity- Wood veneer offers the real look and texture of wood; unlike lesser varieties of veneer such as peel-and-stick printed veneers.

You might be interested in knowing about Kota stone flooring here.

When to use the different types of wood veneer?

Because wood can be chopped, processed, and applied in a variety of ways, there are several forms of wood veneer.

Raw Wood Veneer:

Raw wood veneer has no backing and can be utilized on either side because they look identical until a finish is applied.  The slicing procedure compresses one surface of the veneer while stretching the other, allowing them to stain differently. It is mostly created from hardwood woods, is quite durable, and can be used on both flat and curved surfaces. The grain is not matched throughout manufacturing.

The slicing procedure compresses one surface of the veneer while stretching the other, allowing them to stain differently. It is mostly created from hardwood woods, is quite durable, and can be used on both flat and curved surfaces. The grain is not matched throughout manufacturing.

This implies that if you want to achieve a specific finish, you should consider using another kind of veneer.

You should also try these marble flooring designs for your home as well.

Reconstituted Veneer

Reconstituted veneer is generally built from fast-growing species and comprises many slices of wood fused together.  The completed slab of wood is then split in the opposite direction as the initial slices, so that the edges of the reconstituted veneer become the grain. As a result, the veneer is extremely flexible and can be moulded and bent.

The completed slab of wood is then split in the opposite direction as the initial slices, so that the edges of the reconstituted veneer become the grain. As a result, the veneer is extremely flexible and can be moulded and bent.

Laid-up Veneer

Laid-up veneer is made up of raw veneer pieces that have been joined together to form larger pieces.  This is a wonderful alternative because it can be built to your exact size expectations, appearance, and shape – but it is a time-consuming procedure.

This is a wonderful alternative because it can be built to your exact size expectations, appearance, and shape – but it is a time-consuming procedure.

Know the best flooring options in India here.

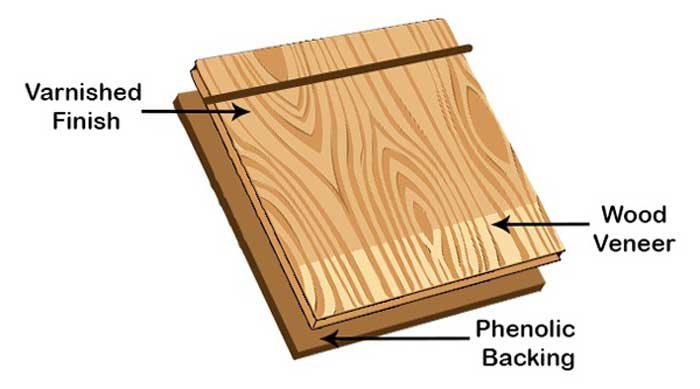

Backed Wood Veneer

Phenolic, paper, foil, and cloth are some of the commonly used materials which help give the entire wood structure a stronger and more flexible touch.  The first material adheres to one side of the veneer, and the grains in the boards are typically matched during production. Because it is more versatile than raw, plain wood veneer and less prone to crack, it can be placed on flat or curvy surfaces.

The first material adheres to one side of the veneer, and the grains in the boards are typically matched during production. Because it is more versatile than raw, plain wood veneer and less prone to crack, it can be placed on flat or curvy surfaces.

Making Process of Wood Veneers

Creating wood veneers is the first step in the production of plywood in various wood mills. A veneer is essentially a thin slice of wood shaved from a log using the rotary cutting or splitting process.  Veneer patterns vary greatly because they are affected by the slope of the cut or the way the wood is cut.

Veneer patterns vary greatly because they are affected by the slope of the cut or the way the wood is cut.  The veneer slices, called leaves, are stored in the sequence in which they were cut. That is, when they are organised into the veneer, they are in order.

The veneer slices, called leaves, are stored in the sequence in which they were cut. That is, when they are organised into the veneer, they are in order.

There are four common forms of cutting:

Flat cutting– Also known as the plain cutting method, this is the most common cutting method. Here, the cut is performed parallel to a line running through the center of the log.

Quarter cutting– A quarter cut is made equal to a radius line in the wood, resulting in a pattern of stripes.

Rift cutting– Such a cutting process is exclusively employed for red and white oak wood. This cut is done slightly off the radius plane connected with quarter cutting.

Rotary cutting– In a rotary cut, the wood is peeled along its growth rings, resulting in a stunning, irregular appearance.

Consider Reading:

Conclusion

When functioning with wood veneers, it is critical to select the correct sort of wood.

This does not only refer to whether the veneer is hardwood or softwood; looking at biological properties can help you select how you will work with it.

Overall, the tree species utilised for veneer are among the greatest building and decorative timbers available.