We all know, it’s a tedious job to monitor the journey of building a home. Since the construction industry is an unorganized sector, there are no rules and regulations defined to control the way people work.

From the quality of the material used to the proportion the material should be used, there are guidelines that must be followed. Likewise, it is equally essential to get the right mix for a strong building.

If you are new to the topic, then keep reading to education yourself about the wall plaster mix ratio and other things that go in the concrete mixture.

Cement

Cement is the basic construction material that is manufactured by limestone and shale. The blended form of cement is good for masonry work and plastering and depending on the type of application the ratio of cement and sand gets changed.

Have a look at beautiful wallpaper coverings for your home

For instance, cement and sand mix can be used for creating a concrete mix, mortar mix, screed mix and plastering mix. Depending on the manufacturer of the cement, it is recommended to have the cement mortar ratio for plastering by mixing required amount of sand, lime and other aggregates.

Different Wall plaster mix ratio

The sand to cement mix ratio is described with help of variety of applications, take a look:

- If you want to plaster with concrete mix then take 1 part cement and 2 part concreting sand.

- Whereas if you plan to use mortar mix for walls, then the ideal cement mortar ratio for plastering would consist 1 part cement and 4 to 5 parts of building sand.

- Similarly when your choice is screed mix, then 1 part cement and 3 to 5 part concreting sand is good enough.

- For plastering, the ideal wall plaster mix ratio becomes from 1 part cement and 3 part plastering sand.

Likewise, cement mortar is used in different proportions for different procedures. Thus, it is beneficial to estimate the amount of cement and aggregates required to calculate the cost of cement for plastering per sq meter.

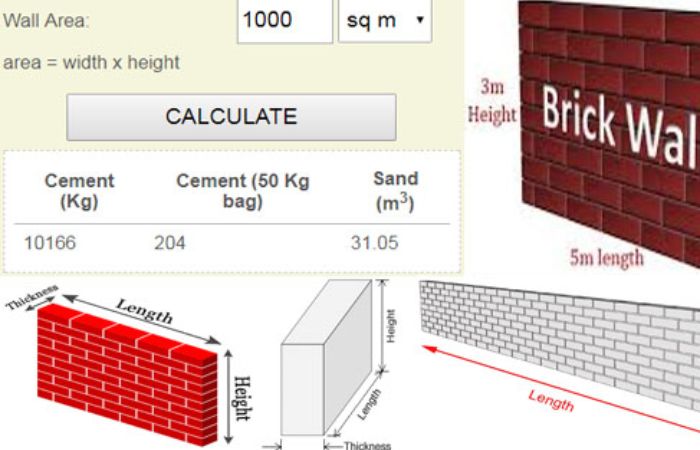

Formula to calculate cement for plastering per sq meter

A simple formula to calculate the volume is (1X1.6/1+x)/0.347;

Where x is the value of the proportion of sand and cement, and 0.0347m3 is the volume of one bag of cement.

Putting values in the example for a cement mortar ratio of 1:6 it concludes that you will need

(1X1.6/1+6)/0.347 = 6.58 bags of cement.

Ideal Ratio of Cement Sand mix for Plastering

Always keep few things in mind before plastering calculation. The thickness should not be more than 15mm and always use good quality of cement. Never use less cement, it won’t create a good bond and never use too much it is also useless.

Take a Quick look at how to remove seelan from walls

- RCC surfaces and walls: 6mm of thickness is advised for plastering RCC walls, and the ideal wall plaster mix ratio can be 1:3 or 1:4.

- RCC under slabs:The ideal thickness of underside of the RCC slabs must be from 6mm to 10mm and 1:3 would be the perfect sand cement ratio.

- Smooth sides of walls: Keep the thickness 12mm for the smoother sides of walls with 1:4 ratios.

- Rough sides of walls: A 9mm or 4.5mm thick plastering is good for rough sides of walls and always keep the ratio 1:4.

- Vertical DPC:For damp proof course, the ratio of cement and sand must be 1:3 where the thickness can go up to 20mm.

Plastering is not only used to make the surface smoother, but a good ratio will make sure that building is strong enough and protected against harsh weather and moisture. Thus, it is important to follow the proper ratio mix for a good construction practice.

Specification Of Wall Plastering

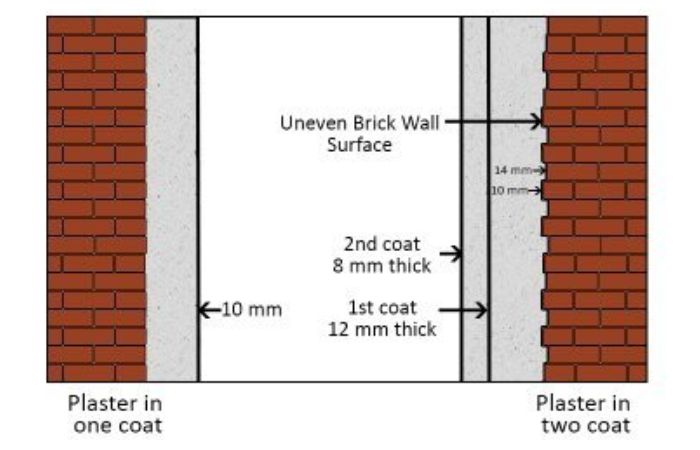

Wall Plastering is a common technique to create a smooth, even surface on interior as well as exterior walls. It involves applying a layer of plaster to the wall surface to achieve a desired finish.

Here are some general considerations:

- Before applying plaster, the wall surface should be clean, free from dust, dirt, loose particles, and any other contaminants

- It is essential to ensure if there are any cracks on the wall, then it should be repaired before plastering

- The ratio of cement, sand and water vary depending on the type of plaster being used. Generally, common ratios include 1:3 (cement to sand) for base coating and 1:4 for finish coating

- Add mixtures like lime or acrylic additives may also be added to improve workability, bonding, and durability

- The base coat can be around 12-15 mm thick, while the finish coat is usually around 5-8 mm thick. However, these thicknesses can vary based on project requirements

- Plaster can be applied manually using a trowel or with the help of a plastering machine

- Curing time can vary depending on the type of plaster used, but generally, it takes several days for the plaster to dry completely

- Once the plaster is cured, it can be finished to achieve the desired appearance. This may include techniques such as sanding, polishing, or texturing the surface

Consider reading: How to cure Brick wall plastering

A Guide to Choose the Right Plastering Material

- Purpose of Plastering: Determine the purpose, whether it is for structural stability, insulation, soundproofing or aesthetic enhancement.

- Surface Type: Some surfaces such as concrete, masonry, or brick, may require a different type of plaster compared to surfaces like drywall or wood.

- Durability: Assess the durability based on the requirements like for high traffic areas or exterior walls, a more robust weather-resistant plaster may be needed.

- Climatic conditions: In areas with high humidity, you may need a plaster i.e resistant to moisture, cracking or thermal expansion.

- Finishing options: Plastering materials offer different textures, smoothness to intricate designs and patterns.

- Budget: Consider your budget, different plastering materials have varying costs, and some may require additional labor or specialized application techniques, which can impact the overall cost.

CONCLUSION

In conclusion, the ideal cement and sand ratio for wall plastering can vary depending on the specific requirements of the project and the desired finish. However, a commonly used ratio for wall plastering is 1:3, which means one part cement to three parts sand. This ratio is typically used for the base coat or undercoat of plaster.

It’s important to note that the cement and sand ratio may be adjusted based on factors such as the type of plaster being used, the condition of the wall surface, and the project’s specific needs. For instance, in some cases, a ratio of 1:4 (one part cement to four parts sand) may be used for the finish coat to achieve a smoother and more refined surface.

Additionally, the addition of admixtures or additives to the plaster mix can further enhance its workability, bonding, and durability. Lime or acrylic additives are sometimes incorporated to improve the performance of the plaster.

After finishing plastering, have a look at unique ways to decorate a wall

I always get confused about the cement and sand ratio for wall plastering. And this method is so technique sensitive that even a slight change in the ratio will result in a completely different texture. I will definitely go through the details you have shared. Hopefully it will help me a lot!